Step into the world of manufacturing innovation where precision meets efficiency – welcome to a realm where filling machines reign supreme. From quenching our thirst with beverages to ensuring medications reach us accurately, filling machines play a pivotal role in various industries beyond what meets the eye. Let’s dive deeper into the versatility and impact of these unsung heroes across different sectors.

The evolution of filling technology

Filling machines have come a long way since their inception, evolving alongside technological advancements. From manual filling processes to automated systems, the evolution of filling technology has revolutionized efficiency and accuracy in various industries.

In the past, filling machines were simple and limited in their capabilities. However, with the integration of sensors, software, and robotics, modern filling machines can now handle a wide range of products with precision and speed.

The development of servo-driven technology has enabled filling machines to adjust fill volumes on the fly, ensuring consistent product quality. Additionally, innovations like clean-in-place (CIP) systems have streamlined cleaning processes for enhanced hygiene standards.

As consumer demands continue to evolve, so does filling technology. Manufacturers are constantly improving machine designs to meet the ever-changing needs of different industries. The future holds exciting possibilities for even more advanced and efficient filling solutions that will further enhance production processes across diverse sectors.

The benefits of using filling machines in various industries

Filling machines offer a multitude of benefits across various industries, revolutionizing the way products are packaged and distributed. One key advantage is precision – these machines ensure accurate filling quantities, reducing waste and maximizing efficiency. Additionally, they improve overall production speed, allowing companies to meet high demands in a timely manner.

Another significant benefit is consistency; filling machines maintain uniform product quality from the first fill to the last, enhancing brand reputation and customer satisfaction. Moreover, these machines enhance safety standards by minimizing human contact with products during the filling process.

Furthermore, filling machines help reduce labor costs by automating repetitive tasks while also decreasing the risk of errors or contamination. This not only improves operational efficiency but also ensures compliance with regulatory requirements in different industries.

Applications of filling machines in the food and beverage industry

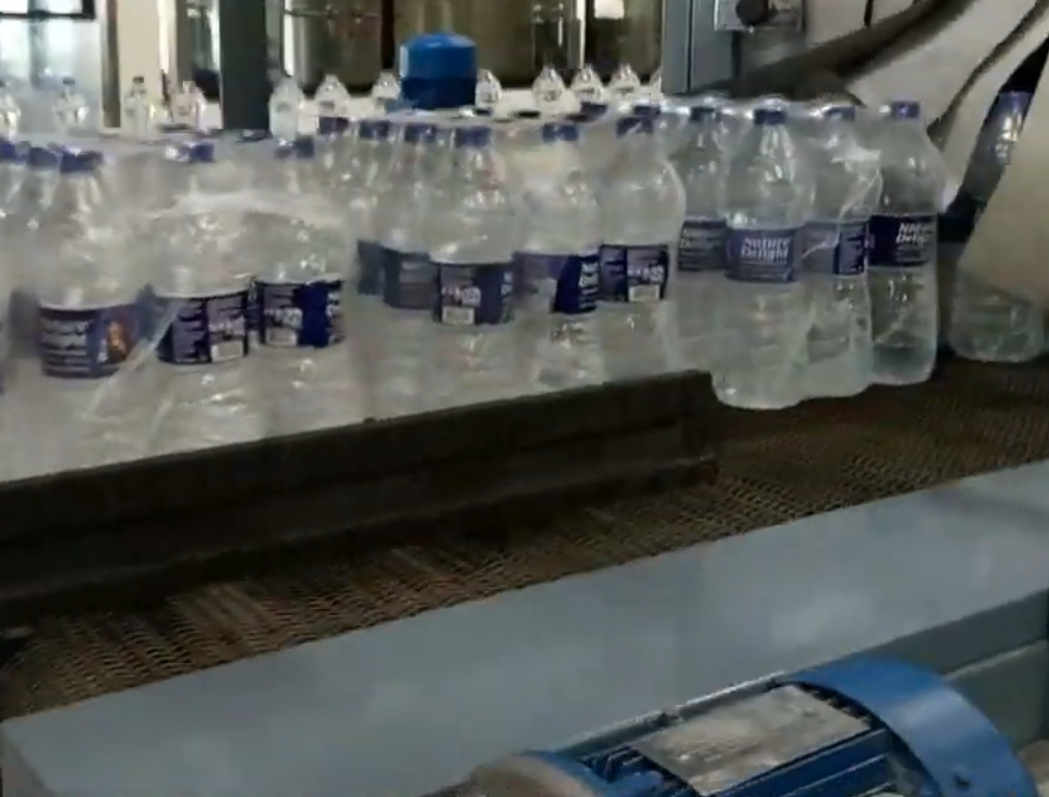

Filling machines play a crucial role in the food and beverage industry, ensuring efficiency and accuracy in packaging various products. From bottling sauces to filling bags with snacks, these machines streamline production processes and maintain consistency in product quality.

In the realm of beverages, filling machines are used to package a wide range of drinks – from carbonated sodas to fresh juices. These machines can handle different viscosities and carbonation levels with precision, catering to diverse consumer preferences.

When it comes to solid foods like grains or powders, filling machines ensure accurate weight measurements for each package. This level of accuracy is essential for meeting regulatory requirements and maintaining customer satisfaction.

Moreover, in the fast-paced world of convenience foods, filling machines enable quick and efficient packaging of ready-to-eat meals or snacks. Whether it’s sealing containers or pouches, these machines help meet market demands effectively while reducing manual labor costs.

Filling machines in the pharmaceutical industry

When it comes to the pharmaceutical industry, precision and accuracy are paramount. Filling machines play a crucial role in ensuring that medications are dispensed efficiently and safely. These machines can handle a wide range of products, from tablets and capsules to syrups and creams.

In pharmaceutical manufacturing, contamination control is critical to maintain product integrity. Filling machines equipped with advanced technology help minimize the risk of contaminants entering the production process. Additionally, these machines can be tailored to meet specific dosage requirements for different medications.

By automating the filling process, pharmaceutical companies can increase their productivity while reducing human error. This not only ensures consistency in product quality but also enhances overall operational efficiency. Moreover, filling machines in the pharmaceutical industry adhere to strict regulatory standards set by organizations like the FDA.

Filling machines have revolutionized how medications are packaged and distributed in the pharmaceutical sector. Their versatility and reliability make them indispensable tools for meeting the demands of this highly regulated industry.

Filling machines for household and personal care products

When we think of filling machines, our minds often jump to the production lines of beverage companies churning out bottles of soda or water. However, these versatile machines find their place in a wide array of industries beyond beverages. One such industry that greatly benefits from filling machines is household and personal care products.

From shampoo and lotions to cleaning solutions and detergents, filling machines play a crucial role in efficiently packaging these everyday essentials. With precise measurements and consistent fills, manufacturers can ensure product quality while maximizing productivity.

Filling machines designed for household and personal care products come equipped with features tailored to the specific needs of these industries. Whether it’s different viscosities, foaming properties, or bottle shapes, modern filling technology can handle a variety of product requirements with ease.

By streamlining the packaging process and reducing waste through accurate fills, filling machines contribute to cost savings for manufacturers while meeting consumer demands for convenience and reliability. In an increasingly competitive market where speed-to-market is essential, investing in high-quality filling equipment becomes a strategic advantage for companies looking to stay ahead in the game.

Environmental impact and sustainability efforts with filling machines

As industries strive to become more environmentally conscious, the role of filling machines in sustainability efforts has come into focus. These machines are designed to minimize waste by precisely dispensing the right amount of product, reducing overfill and spillage.

Furthermore, modern filling machines are equipped with advanced technology that allows for efficient energy consumption during operation. This not only cuts down on electricity usage but also contributes to a lower carbon footprint for manufacturing processes.

In addition to waste reduction and energy efficiency, many filling machines now feature eco-friendly materials in their construction. Companies are opting for sustainable options like recycled plastics or biodegradable components to lessen their impact on the environment.

By integrating environmental considerations into the design and operation of filling machines, industries can make significant strides towards achieving sustainability goals while maintaining high levels of productivity and efficiency.

Future advancements and innovations in filling technology

As technology continues to advance, filling machines are also evolving to meet the changing needs of various industries. The future holds promising innovations in filling technology that aim to increase efficiency, accuracy, and sustainability.

One exciting development is the integration of artificial intelligence (AI) and machine learning algorithms into filling machines. This allows for real-time monitoring and adjustments, optimizing the filling process for maximum precision.

Moreover, there is a growing focus on developing eco-friendly solutions in filling technology. Manufacturers are exploring sustainable materials and methods to reduce waste and environmental impact.

Additionally, advancements in robotics and automation are reshaping how filling machines operate. Robotic arms equipped with sensors can handle complex tasks with speed and reliability, revolutionizing production lines.

The future of filling technology looks bright as innovators continue to push boundaries and explore new possibilities for enhancing efficiency and sustainability across different industries.

Conclusion: The endless possibilities of filling machines across industries

As we’ve delved into the world of filling machines, it becomes evident that these versatile tools are not limited to just one industry. From food and beverage to pharmaceuticals, household products, and beyond, filling machines play a crucial role in streamlining production processes and ensuring efficiency.

The evolution of filling technology has led to increased precision, speed, and customization options for businesses across different sectors. By embracing filling machines, industries can benefit from improved productivity, reduced waste, and enhanced sustainability efforts.

Looking ahead, advancements in filling technology continue to push boundaries and open up new opportunities for innovation. As industries strive to meet growing demands while minimizing environmental impact, filling machines stand at the forefront of modern manufacturing practices.

In conclusion: The adaptability and endless possibilities of filling machines underscore their importance as indispensable assets for businesses seeking efficient solutions across various industries.